Standard Bathroom Faucet Supply Line Sizes

Bathroom faucet supply lines are the unsung heroes of plumbing, quietly delivering water to your sink, tub, or shower. But just like any good hero, they come in different sizes, and understanding these sizes is crucial for a smooth installation and long-lasting performance.

Standard Bathroom Faucet Supply Line Sizes, What size are bathroom faucet supply lines

The most common bathroom faucet supply line sizes are 1/2 inch (12.7 mm) and 3/8 inch (9.5 mm). These sizes are used for both hot and cold water supply lines. The 1/2 inch size is the most prevalent, providing adequate flow for most bathroom fixtures. The 3/8 inch size is often used for smaller fixtures or when space constraints exist.

Types of Bathroom Faucet Supply Lines

There are three main types of bathroom faucet supply lines:

- Braided Supply Lines: These are flexible lines with a braided stainless steel outer layer and a rubber inner core. Braided supply lines are the most common type due to their durability, flexibility, and affordability. They are typically available in 1/2 inch and 3/8 inch sizes.

- Flexible Supply Lines: Similar to braided supply lines, flexible supply lines are also flexible and made of a rubber inner core. However, their outer layer is made of a smooth plastic material instead of braided steel. They are often available in 1/2 inch and 3/8 inch sizes.

- Rigid Supply Lines: Rigid supply lines are made of copper or PEX tubing. They are not flexible and are typically used in concealed installations or when a more robust connection is required. Rigid supply lines are typically available in 1/2 inch and 3/8 inch sizes.

Examples of Bathroom Faucet Supply Line Sizes

To illustrate the connection between bathroom faucets and supply line sizes, let’s consider some common examples:

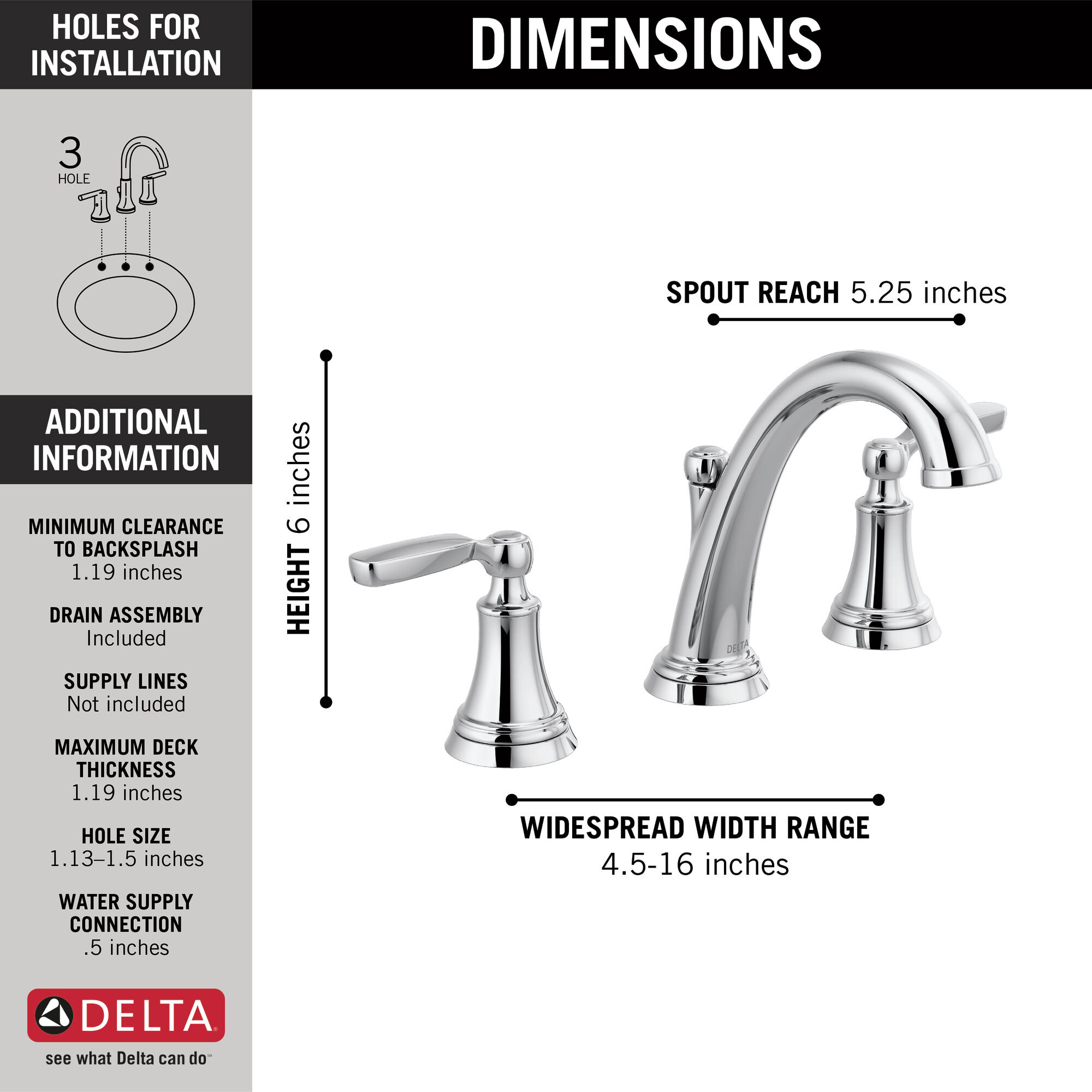

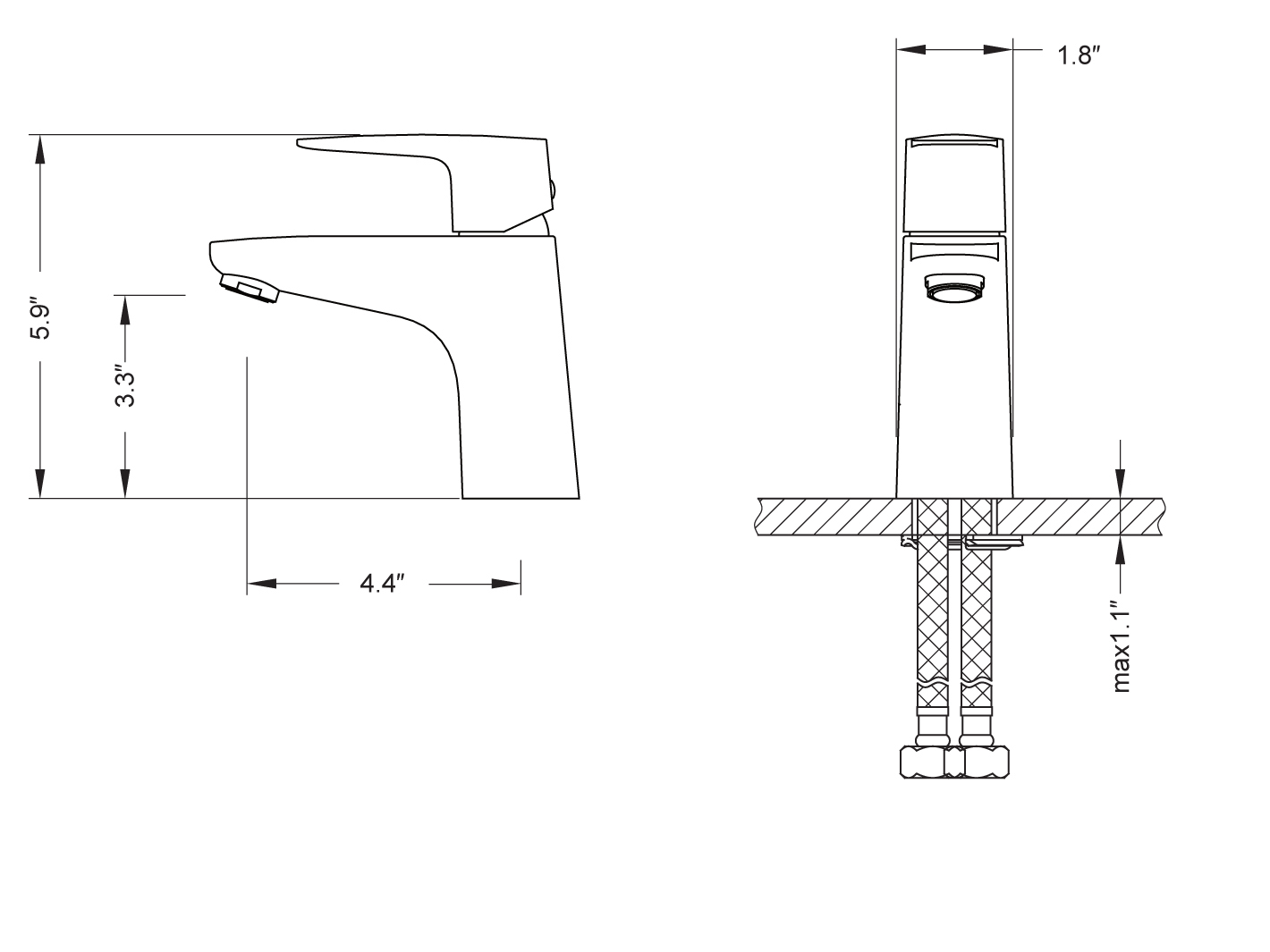

- Single-Handle Bathroom Faucet: These faucets typically use 1/2 inch supply lines for both hot and cold water.

- Two-Handle Bathroom Faucet: Similar to single-handle faucets, these also typically use 1/2 inch supply lines for hot and cold water.

- Shower Faucet: Shower faucets can use 1/2 inch or 3/8 inch supply lines, depending on the specific model and water pressure requirements.

- Tub Spout: Tub spouts typically use 1/2 inch supply lines for hot and cold water.

Factors Affecting Bathroom Faucet Supply Line Size

Choosing the right size for bathroom faucet supply lines is crucial for optimal water flow and pressure. This ensures a smooth and efficient water experience, without any annoying surprises like sputtering or low pressure. Let’s explore the key factors that influence this important decision.

Water Pressure’s Impact on Supply Line Size

Water pressure plays a significant role in determining the appropriate size of supply lines. Higher water pressure necessitates larger supply lines to accommodate the increased flow of water. Conversely, lower water pressure allows for the use of smaller supply lines.

For instance, if your home has a water pressure of 60 PSI, you’ll need larger supply lines compared to a home with a water pressure of 40 PSI.

Faucet Flow Rate’s Influence on Supply Line Size

The flow rate of your faucet, measured in gallons per minute (GPM), is another important factor to consider. Higher flow rates require larger supply lines to ensure adequate water delivery.

For example, a high-flow faucet with a flow rate of 2.5 GPM will need larger supply lines than a standard faucet with a flow rate of 1.5 GPM.

Faucet Type’s Role in Determining Supply Line Size

The type of faucet you choose also affects the size of the supply lines. Single-handle faucets generally require smaller supply lines than double-handle faucets, as they have a single inlet for water.

For instance, a single-handle kitchen faucet typically uses 1/2-inch supply lines, while a double-handle kitchen faucet might use 3/8-inch supply lines.

Choosing the Right Bathroom Faucet Supply Line Size

Selecting the appropriate bathroom faucet supply line size is crucial for optimal water pressure and flow rate. A correctly sized supply line ensures smooth water delivery to your faucet, preventing issues like low water pressure, noisy operation, and potential damage to your plumbing system.

Determining Existing Supply Line Size

To ensure you select the right size for your new supply lines, it’s essential to measure the existing ones. Here’s a step-by-step guide:

- Turn off the water supply to the bathroom. This is crucial for safety and prevents water from spilling during the measurement process.

- Locate the supply lines connected to your existing faucet. They are usually copper or braided stainless steel tubes, typically found behind the faucet or within the wall.

- Measure the outer diameter of the supply lines using a ruler or measuring tape. Measure at a point where the lines are straight and not bent.

- Record the measurements in inches or millimeters. This will help you determine the size of your existing supply lines.

Supply Line Size Comparison

This table compares different supply line sizes with their corresponding water pressure and flow rate capabilities.

| Supply Line Size (inches) | Water Pressure (psi) | Flow Rate (gallons per minute) |

|---|---|---|

| 1/4 | 25-40 | 1-2 |

| 3/8 | 40-60 | 2-4 |

| 1/2 | 60-80 | 4-6 |

Supply Line Size Selection Recommendations

- For standard faucets with moderate flow rate requirements, a 3/8-inch supply line is typically sufficient.

- For high-flow faucets or those with multiple spray settings, a 1/2-inch supply line is recommended to ensure adequate water pressure and flow rate.

- If your plumbing system has low water pressure, consider using 1/2-inch supply lines to compensate for the pressure loss.

- For older homes with outdated plumbing, it’s advisable to consult a plumber to assess the existing system’s capacity and determine the appropriate supply line size.

Installation and Maintenance of Bathroom Faucet Supply Lines: What Size Are Bathroom Faucet Supply Lines

Installing bathroom faucet supply lines is a relatively straightforward process, but it requires careful attention to detail to ensure proper water flow and prevent leaks. Proper installation and regular maintenance are crucial for the longevity and efficient operation of your bathroom faucet.

Connecting Bathroom Faucet Supply Lines

Connecting bathroom faucet supply lines involves attaching them to the shut-off valves and the faucet itself. This process requires specific tools and a basic understanding of plumbing techniques.

- Shut-Off Valves: Begin by turning off the water supply to the bathroom. This is usually done by turning the shut-off valves located beneath the sink. These valves are typically 1/2-inch in size and can be turned clockwise to close the water flow.

- Connecting to the Faucet: Once the water supply is off, you can connect the supply lines to the faucet. The supply lines are typically attached to the faucet using compression nuts. These nuts tighten against the faucet’s inlets, creating a secure seal.

- Connecting to the Shut-Off Valves: After connecting the supply lines to the faucet, connect the other ends to the shut-off valves. This is usually done using a threaded connection. The supply lines are typically threaded with a 1/2-inch female National Pipe Thread (NPT) fitting, which screws onto the 1/2-inch male NPT fitting on the shut-off valves.

- Tightening Connections: When tightening the connections, it is crucial to use a wrench to avoid over-tightening, which can damage the fittings. Hand-tighten the connections first, then use a wrench to give them an additional quarter turn.

- Testing for Leaks: After connecting the supply lines, turn the water supply back on and carefully check for leaks at each connection point. If you find any leaks, tighten the connections slightly and re-check.

Preventing Leaks and Ensuring Proper Water Flow

Preventing leaks and ensuring proper water flow is essential for the safe and efficient operation of your bathroom faucet. Here are some tips:

- Use High-Quality Supply Lines: Invest in high-quality supply lines made from durable materials like braided stainless steel or copper. These materials are less prone to leaks and corrosion.

- Inspect for Damage: Regularly inspect the supply lines for signs of damage, such as cracks, kinks, or corrosion. Replace damaged supply lines immediately to prevent leaks and potential water damage.

- Proper Installation: Ensure the supply lines are properly installed and tightened to prevent leaks. Over-tightening can damage the fittings, while under-tightening can lead to leaks.

- Avoid Excessive Bending: Avoid bending the supply lines excessively, as this can weaken them and lead to leaks. Use flexible supply lines where necessary to avoid excessive bending.

- Use Teflon Tape: Use Teflon tape on the threaded connections of the supply lines to ensure a tight seal and prevent leaks.

Regular Maintenance and Inspection

Regular maintenance and inspection are crucial for ensuring the longevity and safe operation of your bathroom faucet supply lines.

- Inspect for Leaks: Regularly inspect the supply lines for any signs of leaks, such as dripping water or dampness around the connections.

- Check for Corrosion: Check the supply lines for signs of corrosion, which can weaken the material and lead to leaks.

- Check for Damage: Look for any signs of damage, such as cracks, kinks, or abrasions, which can compromise the integrity of the supply lines.

- Replace Worn or Damaged Lines: Replace any worn or damaged supply lines immediately to prevent leaks and potential water damage.